Tips for Sanding and Finishing Particle Board Like a Pro

Particle board is a versatile material that can transform any woodworking project from ordinary to extraordinary. Its durability and affordability make it a popular choice, but achieving a professional finish requires the right techniques and tools. Whether you're a seasoned pro or a DIY enthusiast, here are 10 essential tips to help you achieve a flawless finish on your particle board projects.

Understanding Particle Board: Properties and Challenges

Particle board is made from wood particles that are bonded together with resin and glue. While it offers significant advantages, such as strength and affordability, it also presents unique challenges. Common issues include uneven surfaces, visible glue joints, and softness that affects sanding. Understanding these characteristics is the first step to successfully sanding and finishing your particle board.

Selecting the Right Tools for Sanding Particle Board

The right tools are essential for a smooth and even finish. Start with the appropriate sandpaper grit, beginning with a coarse grit (60 or 80) to remove any rough spots and then transitioning to finer grits (150 and 220) for a smooth surface. Use an orbital sander for larger areas and a hand sanding block for detailed work. These tools will help you achieve a consistent and professional-looking finish.

Sanding Techniques for Different Surfaces and Joints

Mastering the proper sanding techniques is crucial for handling different surfaces and joints effectively. For flat surfaces, use gentle, circular motions to avoid creating swirl marks. When working on edges and corners, apply even pressure and maintain a steady hand to prevent marks. Dealing with glue joints can be tricky, but using a fine grit sandpaper and sanding in one direction can help minimize their visibility.

Finishing Methods for Particle Board: Polishing and Protecting the Surface

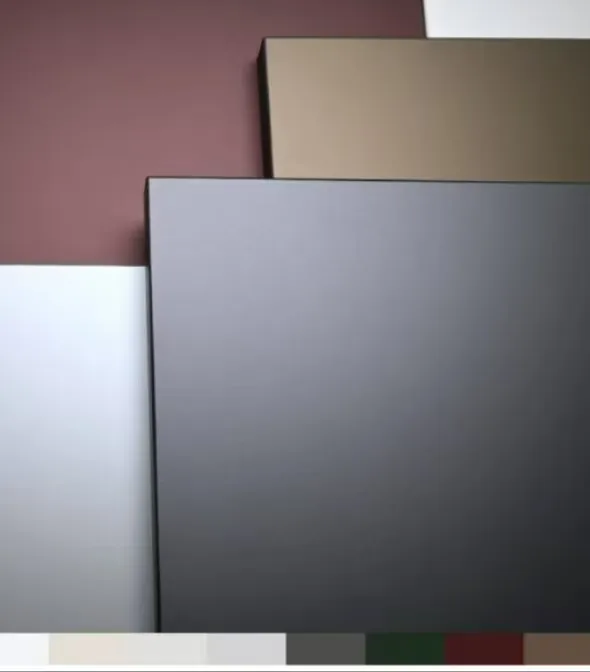

Choosing the right finishing method is key to protecting your particle board and enhancing its appearance. Common options include staining, varnishing, lacquering, and painting. Staining allows you to add depth and color, while varnishing and lacquering provide a durable, protective finish. Painting is a better option for more extensive coverage, but it needs to be done carefully to avoid peeling.

Tips for Achieving a Professional Finish on Particle Board

Here are a few practical tips to guide you through achieving a professional finish:

1. Consistency Is Key: Ensure even application of sandpaper and finish to avoid any noticeable differences. Take your time and keep a steady hand.

2. Avoid Common Mistakes: Marking your piece or creating uneven surfaces are common pitfalls. Double-check your work and be meticulous.

3. Reclaiming Failed Finishes: If you make a mistake or the finish doesnt look as expected, dont worry. Reapply the stain or finish to correct any issues.

4. Proper Ventilation and Temperature: Always work in a well-ventilated area and apply finishes at the recommended temperature to ensure quality results.

Maintenance and Longevity of Particle Board Finishes

Proper maintenance is crucial for the longevity of your finished particle board. Regular cleaning with mild detergent and water will keep your project looking its best. Store your tools and materials in a dry, well-ventilated area to prevent warping or discoloration.

Case Study: A Pros Approach to a Real-World Particle Board Project

Imagine you're a professional woodworker tasked with finishing a custom dining table using particle board for the tabletop and shelves. Heres how you might approach the project:

1. Initial Assessment: Inspect the particle board for any defects or imperfections. Check for unevenness or moisture damage.

2. Sanding Process: Start by lightly sanding the tabletop with a coarse grit sandpaper to remove any excess thickness and create a smooth surface. Transition to finer grits (150 and 220) to achieve a uniform finish.

3. Finishing: For the tabletop, apply a stain to complement the wood color. Apply two coats, allowing each to dry completely before moving on to the next. For the shelves, apply a varnish for a glossy, protective finish.

The Importance of Attention to Detail in Sanding and Finishing Particle Board

Sanding and finishing particle board requires dedication and attention to detail. By following these tips, you can transform your project into a masterpiece. Whether you're working on a small tabletop or a large cabinet, these techniques will help you achieve a professional finish that lasts.

Stay patient, stay consistent, and happy woodworking!