FAQs About Using PVC Edge Banding in Furniture Manufacturing

Applications of PVC Edge Banding

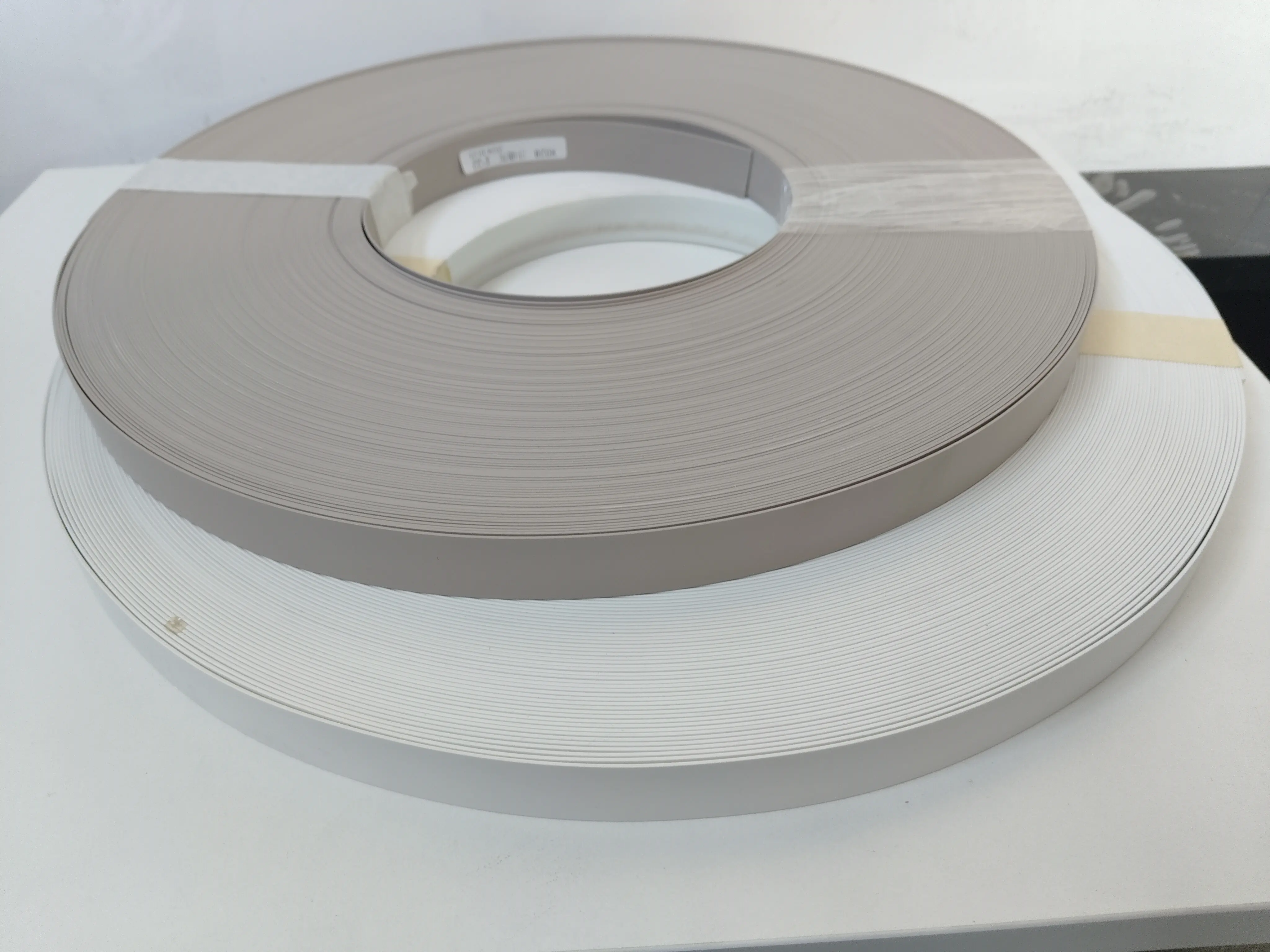

In furniture manufacturing, PVC edge banding offers several advantages. Its durability and resistance to wear make it ideal for components that require long service lives, such as table edges, cabinet frames, and drawer fronts. This materials seamless application contributes to a polished, professional finish, enhancing the overall look of the furniture.

Common Applications

- Table Components: PVC edge banding is commonly used on table edges, providing a seamless and durable finish.

- Cabinet Frames: It is frequently applied to cabinet frames, ensuring long-lasting durability and a clean aesthetic.

- Drawer Fronts: PVC edge banding is also used for drawer fronts, enhancing both the look and structural integrity of the drawers.

- Door Fronts: It is applied to door fronts to provide a uniform and stylish edge.

Benefits of Using PVC Edge Banding

While PVC edge banding offers significant benefits, it also presents some challenges. One of its primary advantages is its durability. PVC edge banding resists wear and tear, ensuring that furniture remains in excellent condition for years to come. Additionally, its ease of installation and minimal maintenance contribute to a streamlined production process, making it a cost-effective option for manufacturers.

Flexibility and Strength

The flexibility of PVC edge banding ensures compatibility with different materials, making it easier to apply on various surfaces. This flexibility is particularly useful when working with irregularly shaped edges. The materials strength allows it to withstand the rigors of daily use, ensuring that furniture components remain intact.

Ease of Installation

Easy installation is a key benefit of PVC edge banding. It requires minimal tools and can be applied using standard adhesives, making the process efficient and straightforward. This ease of use reduces labor costs and speeds up production, making it an attractive choice for manufacturers.

Choosing the Right PVC Edge Banding for Your Project

When selecting PVC edge banding for a project, several factors should be considered:

- Color Options: High-quality PVC edge banding often comes in a variety of colors, allowing for customization to match specific project requirements. This flexibility facilitates seamless integration with other materials and design elements.

- Flexibility: The flexibility of PVC edge banding ensures compatibility with different materials, making it easier to apply on various surfaces. This flexibility is particularly useful when working with irregularly shaped edges.

- Ease of Installation: Easy installation is a key benefit of PVC edge banding. It requires minimal tools and can be applied using standard adhesives, making the process efficient and straightforward.

- Environmental Impact: Considering the environmental impact is crucial in todays market. Eco-friendly manufacturing processes, such as recycling and minimizing waste, contribute to a sustainable supply chain. Manufacturers can reduce their environmental footprint by adopting these practices.

Troubleshooting Common Issues

Troubleshooting common issues with PVC edge banding involves addressing potential problems such as adhesion issues and peeling. Proper application techniques are crucial to prevent these issues. Using the right temperature and pressure, along with the appropriate adhesion agents, can ensure a strong and lasting bond. Regular maintenance is also essential to keep the edge banding in optimal condition.

Common Issues and Solutions

For instance, if you notice that the edge banding is peeling, it might be due to inadequate adhesion or improper temperature during application. Ensure that you use a suitable adhesive and apply the banding at the right temperature to maintain a strong bond. Regular inspections and timely maintenance can help prevent such issues and extend the life of your furniture.

Sustainable Practices

Incorporating sustainable practices into the use of PVC edge banding is increasingly important in todays environmentally conscious market. Eco-friendly manufacturing processes, such as recycling and minimizing waste, contribute to a sustainable supply chain. By adopting sustainable practices, manufacturers can reduce their environmental footprint while maintaining high standards of quality and performance.

Eco-Friendly Practices

For example, manufacturers can recycle PVC edge banding waste and repurpose it for other sustainable uses. This not only reduces waste but also lowers the demand for new materials, contributing to a more sustainable production process.

Conclusion

In conclusion, PVC edge banding plays a vital role in modern furniture manufacturing, offering durability, ease of installation, and a professional finish. While it has its challenges, its benefits make it a responsible and sustainable choice for manufacturers. By embracing sustainable manufacturing practices, the furniture industry can continue to utilize PVC edge banding responsibly, contributing to both quality and environmental sustainability.

This approach to PVC edge banding provides a clear understanding of its applications, benefits, and the importance of sustainability in the industry. By making these adjustments, the article becomes more engaging, concise, and impactful, better meeting the needs of a social media audience.